Our R&D mission

Our R&D efforts focus on the development of reliable, high-performance solutions for the most demanding conditions (extreme temperatures, high mechanical stress, etc.) and creating custom solutions to meet the most specific requirements.

In line with our CSR policy, our technology roadmap focuses on the development of high-performance and sustainable solutions.

- Improve product’s health, safety and environmental (HSE) profile, through new non-hazardous technologies

- Reduce environmental impacts of our activities, through low-carbon footprint lubricants formulated from bio-based synthetic esters and innovative manufacturing processes

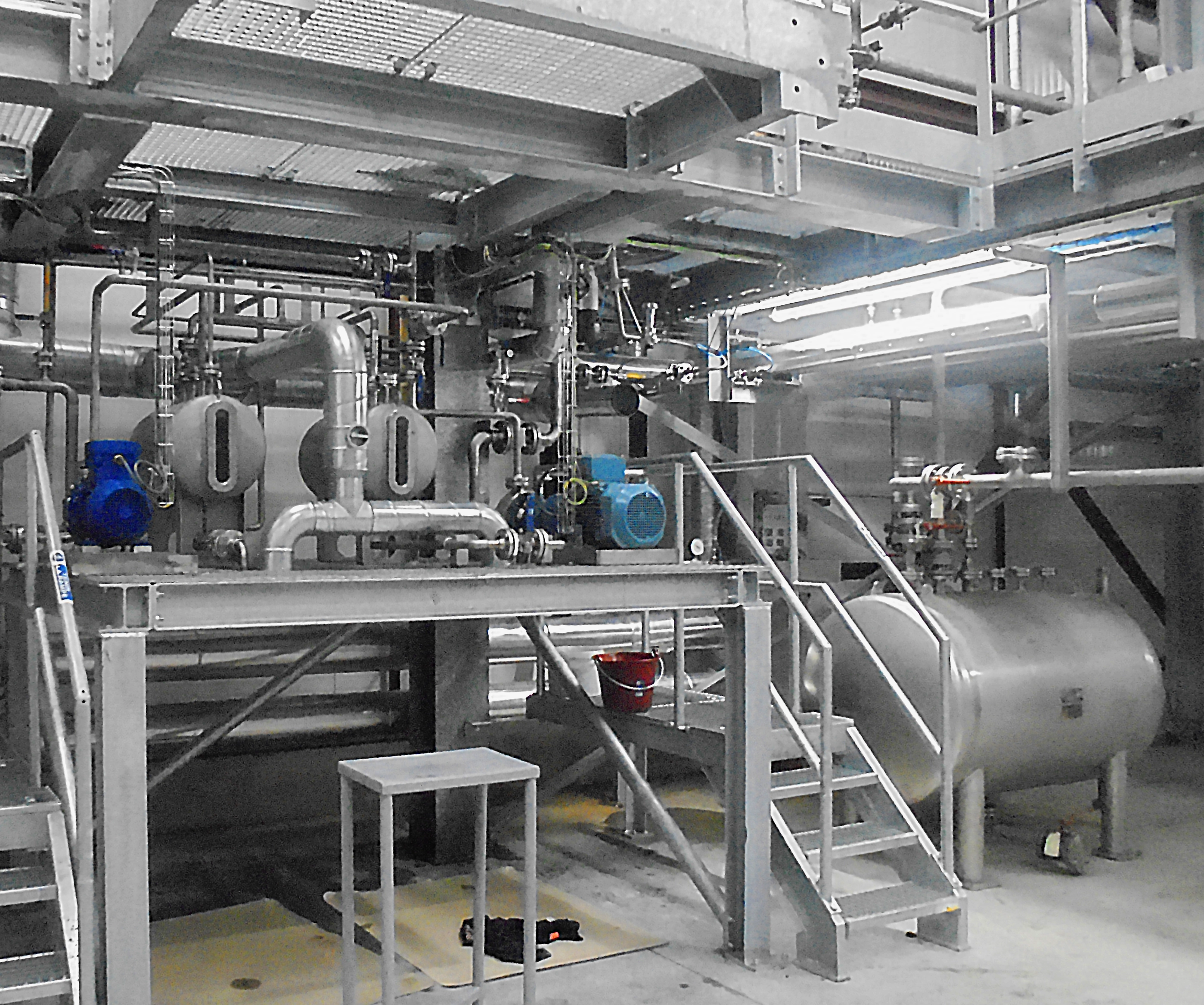

The industrialization phase of new products and processes is carried out in close collaboration with the Process departments at our sites in Tournai, Belgium, and soon in Newnan, USA.

The Process department at our Tournai site features a 250-liter pilot unit. This unit is representative of our 50 m³ industrial lines, and is compatible with a 10 m³ line as an intermediate step, if needed. By the end of 2025, a 50-liter pilot unit dedicated to the development of innovative processes aimed at reducing manufacturing times will be installed in our R&D laboratory.

A dedicated team

Our R&D team consists of a total of 33 engineers, PhD students, technicians, and work-study students.

Our R&D is divided into three departments: Aeronautics & Defense, Greases, and Industry & Automotive. They each have similar objectives in their respective fields: ester synthesis, development of new bases or additives, formulation of finished products, and optimization of manufacturing processes in collaboration with the site’s Process team.

The Organic Synthesis department works on synthesizing new additives, molecules, or bases, which are then made available to formulation chemists.

The Analysis department develops analysis methods to monitor synthesis processes. It is also responsible for conducting in-depth analyses of our products, and providing technical support to our plants or customers.

The Metrology & Quality Control laboratory is responsible for testing our R&D products according to standards or customer requirements. It also ensures compliance of our equipment (around 500 different tests).

The Sales Support department ensures the in-service monitoring of our lubricants through joint studies with customers and analyses any issues encountered.

This department studies the interactions between our lubricants and surfaces, whether metallic or not, to ensure they meet the required anti-wear and extreme pressure properties.

This is a newly established department that focuses on modelling the properties of our products based on their chemical structure. It actively contributes to toxicology and ecotoxicity studies (including on biodegradability, carcinogenic, mutagenic, and reprotoxic (CMR) substances, neurotoxicity and endocrine disruption, etc.)

The Technical department oversees research and draws up the technological roadmap in partnership with the CEO and BUs. It also establishes academic and industrial partnerships, manages the patent portfolio, and monitors technological and market developments.

Every year, NYCO invests in acquiring new equipment and upgrading its existing facilities:

- 250L pilot unit at our Tournai site (increasing capacity)

- Grease & oil test bench (tribology)

- Tribometers (tribology)

- TGA / AIT (testing)

- State-of-the-art chromatographic analysis equipment